Is 0.01mm precision a SCAM for magnetic switches keyboard?

📅Dec 18 2024

When you first see a keyboard advertised as having a 0.01mm precision, you may ask immediately…..

“How did you achieve this?” And is this a scam?

As of today, 0.01mm precision hall effect keyboard has been comprehensively tested on Bilibili by Chinese keyboard/technology enthusiasts using different equipment. The 0.01mm precision is built in FW and chip but users would always want to validate by themselves.

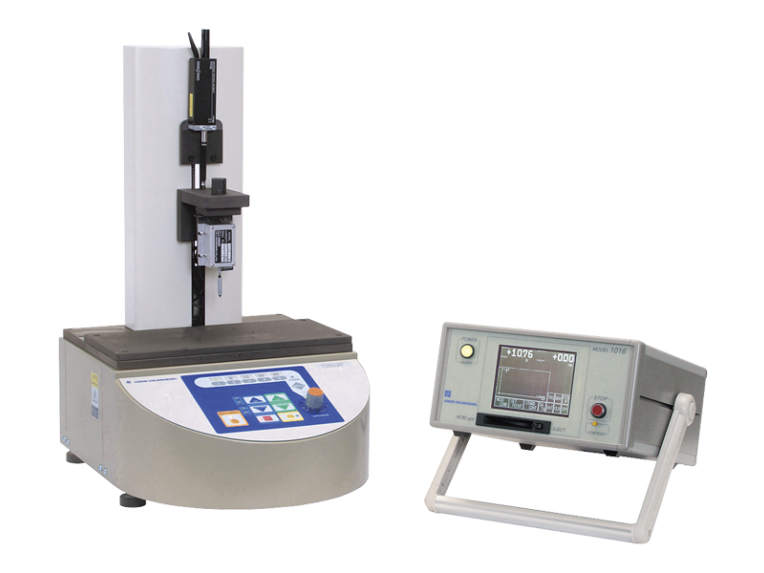

To verify that, most people would purchase a force gauge tester/load tester in 0.001mm magnitude which costs from $1500 (used) to as high as $15000 or more. There isn’t a limitation of the equipment but a force gauge tester would be a reliable “ready to go” machine. If you can manage to have a DIY machine that can have an incremental movement of 0.001mm and effectively record and measure such discrepency changes, then it would work as well.

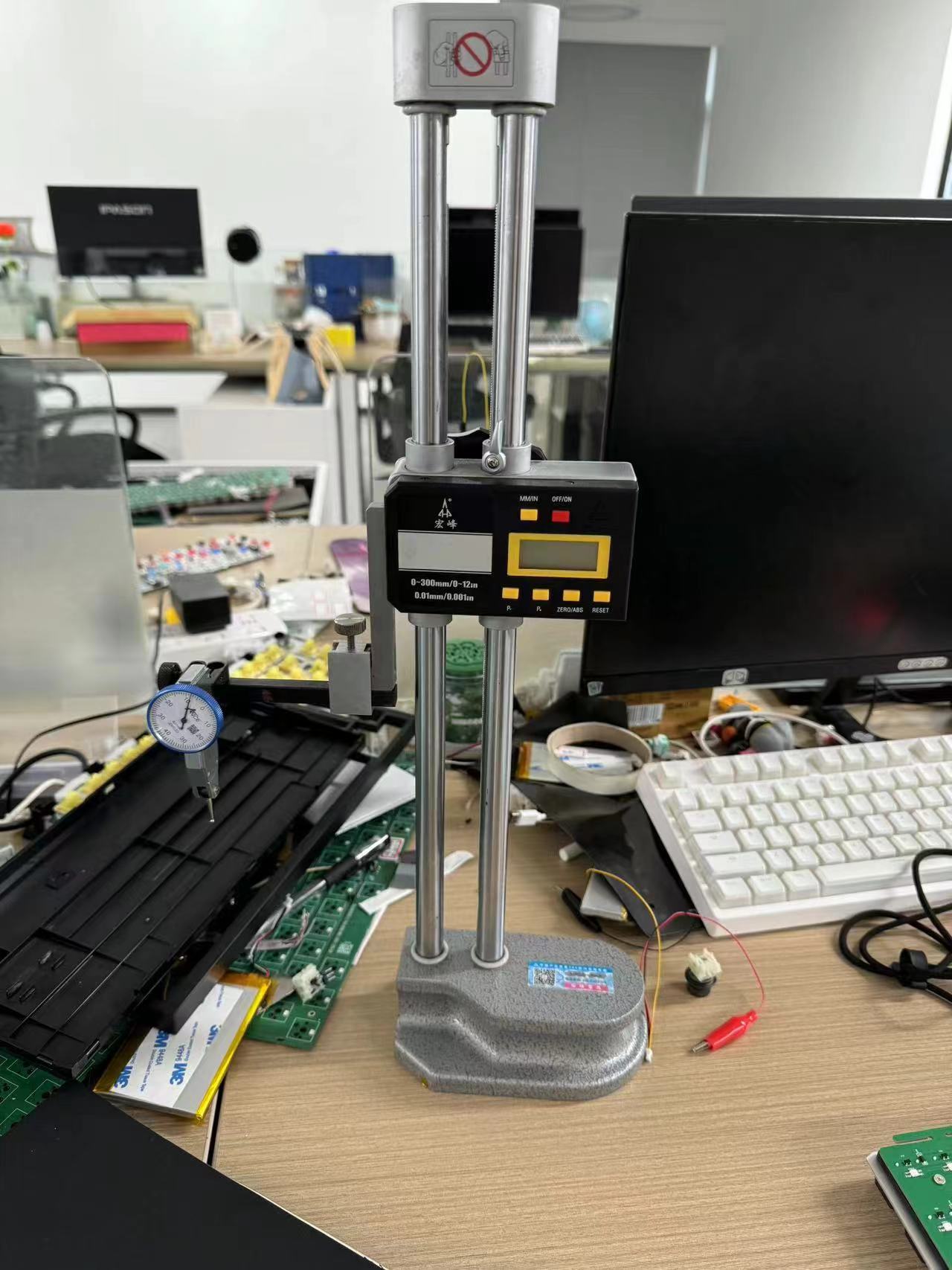

Note when we were testing for 0.1mm precision keyboard, a 0.01mm magnitude force gauge can be used used. And the below gauge from Hong Feng is the most popular one among all for testing the actual actuation point and release point. This digital gauge costs around $200 and is fairly accessible.

However, when it comes down to a 0.01mm precision, devices that can only measure at a magnitude of 0.01mm will be too rough to provide an accurate measurement. The needle or pressing unit of the gauge or machine that attaches to the keyboard must be able to move in increments of 0.001mm with minimal force. Apparently, the precision test would NOT work if the gauge tester requires you to directly move the needle by human hands (which can hardly control at even 0.1mm precision) or with bigger displacement movement of needle that is larger than 0.01mm.

The keyboard will be connected to the computer physically as usual. For example, if you are testing the accuracy of release point, please control the gauge to gradually move the pressing needle so that the keyboard will be pressed at the actuation point. You can set this point as 0. Then you can gradually release the load tester needle in 0.001mm increments to determine at which actuation point (in mm) the keyboard stops input and resets.

The same method can be used to test the initial actuation at 0.1mm and the deadzone.

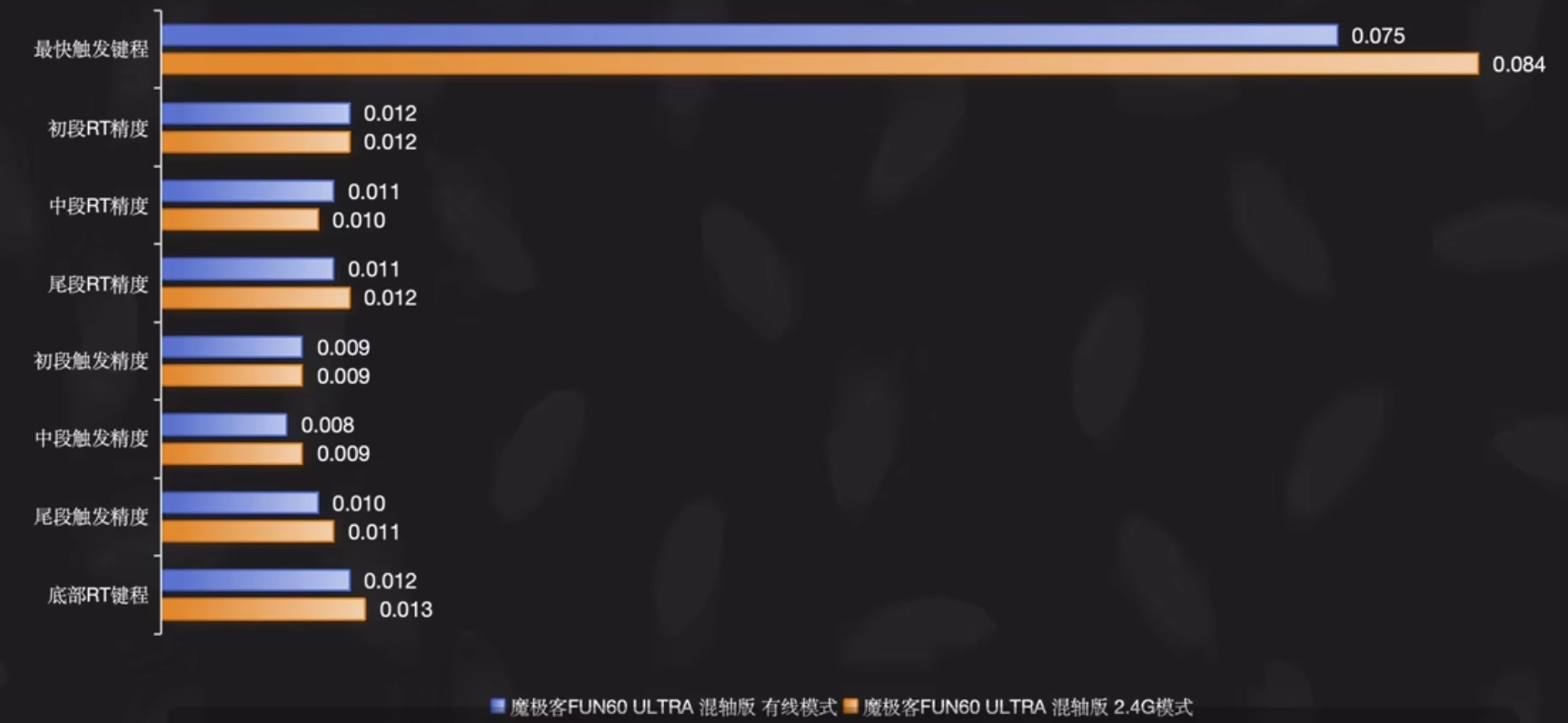

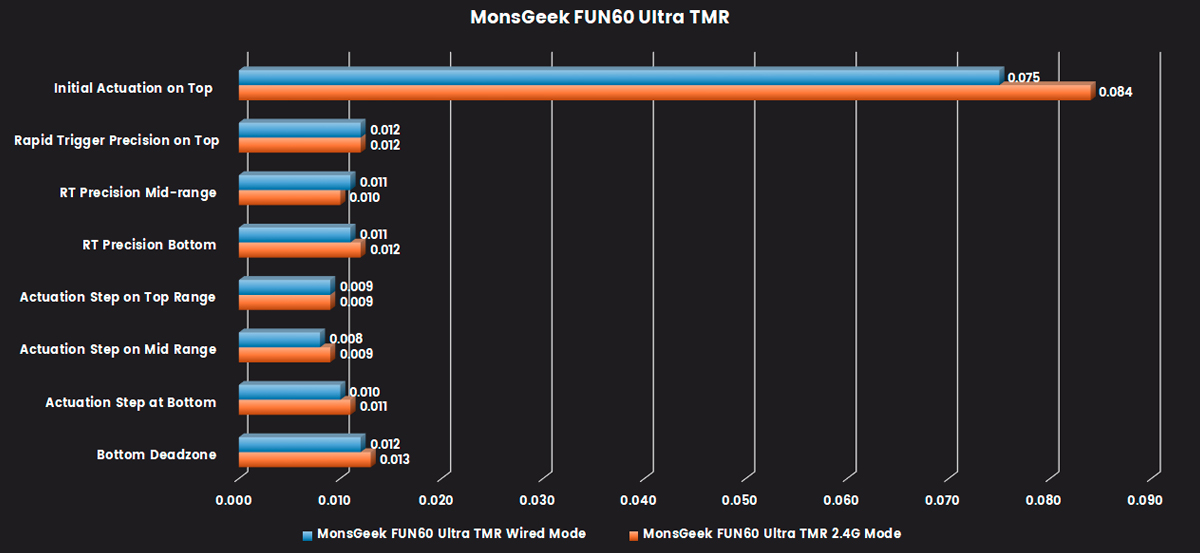

Below are several tests by different influencers with sources:

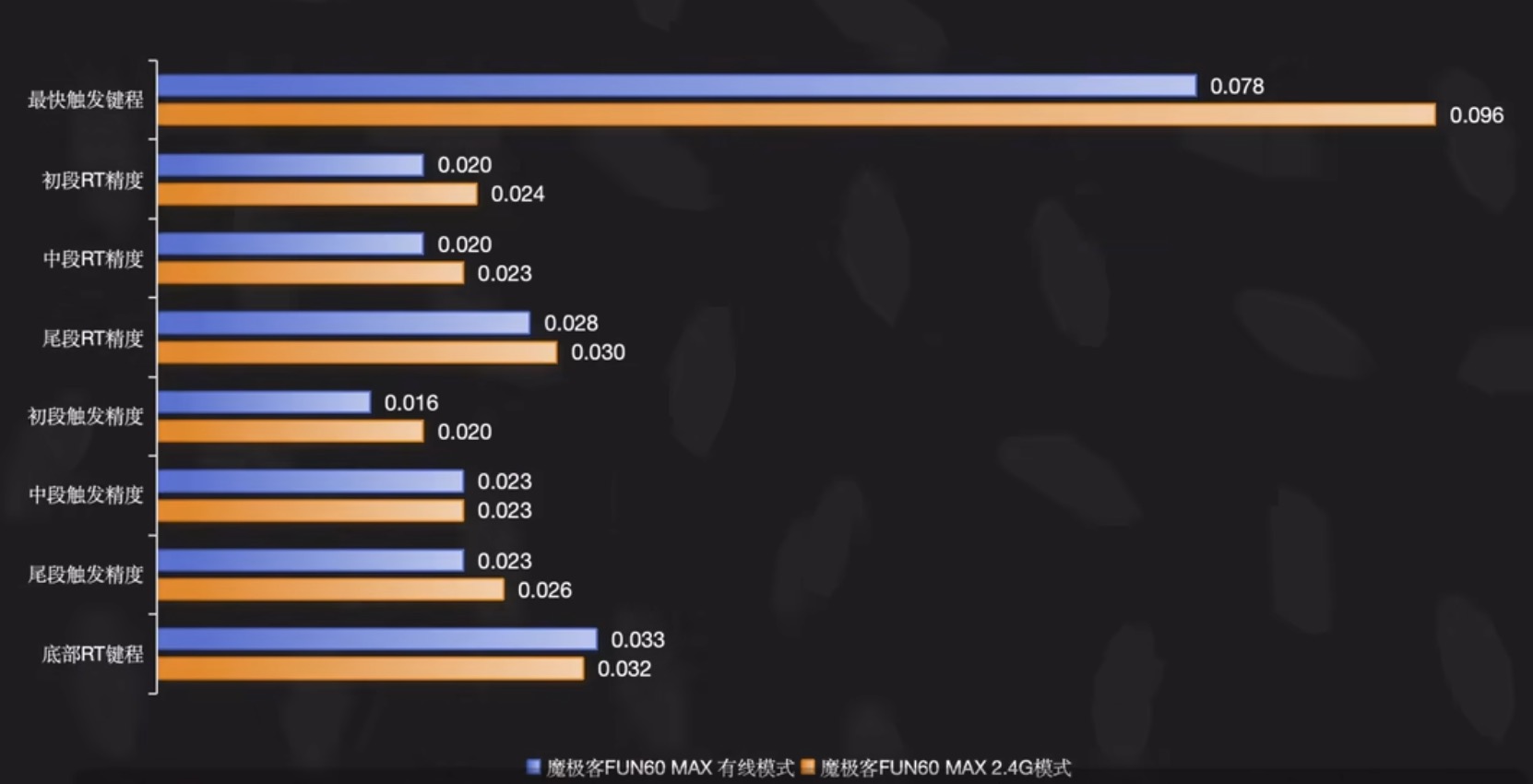

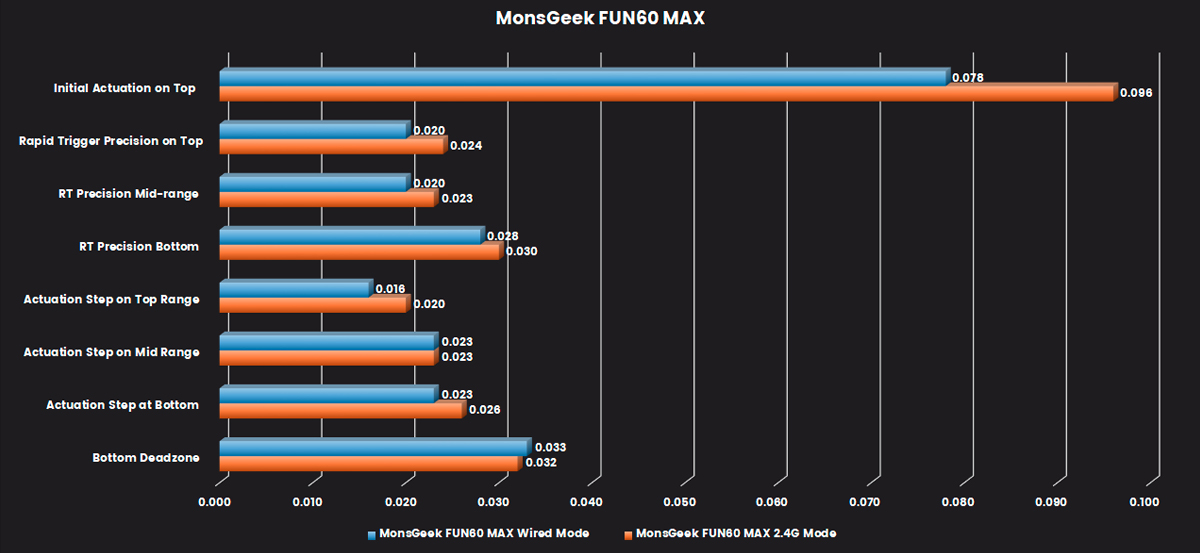

*Source: In外设 (video at 02:05)

in外设 seems to be using 3D printer (based on the Fluidd UI for Klipper) to control movement? It is a very creative way of validating the precision.

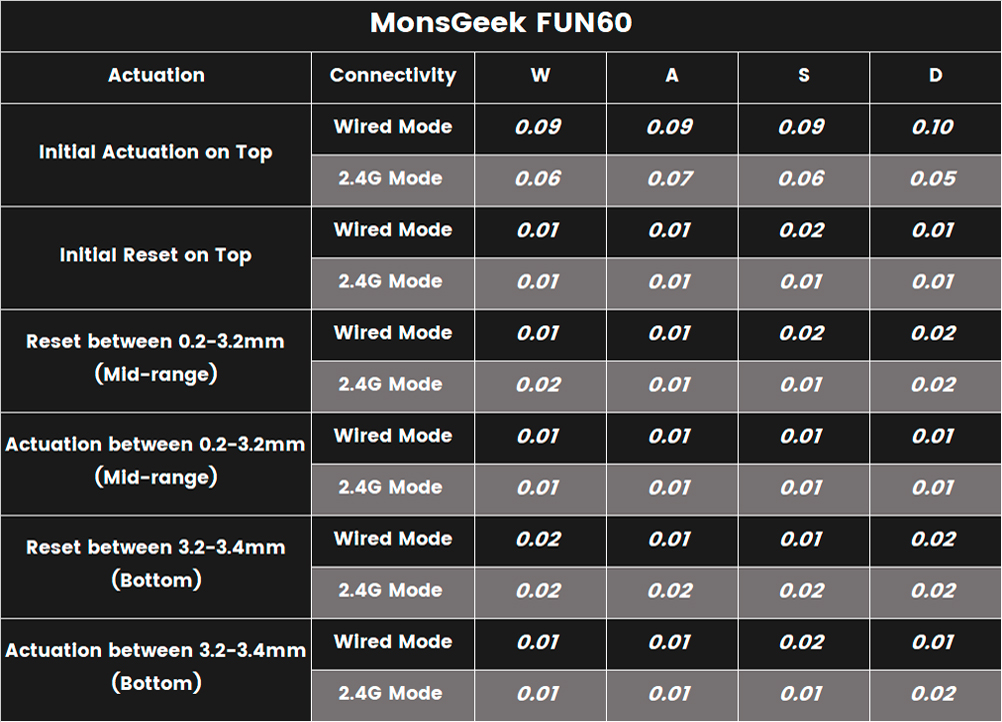

*Source: 键盘侠赤瞳妖 (video at 00:39)

AIKOH 1305VC is the equipment being used by this influencer for the test as he previously disclosed the equipment in his first 0.01mm precision test video.

From those results, we can see the keyboard generally has better precision in actuation in wired mode.

Different machines may generate slightly different results. In this case, it is crucial to check the horizontal comparison of same machine across different keyboards (the source of the videos are disclosed, you can check if you have interests… not okay for us to talk about keebs from other brands) and even different switches can produce varying values.

We will be gradually updating the test results from new sources.

Overall most results tend to be close. 0.01mm precision is not a joke though in certain scenarios you may get 0.02mm based on the equipment and the testing environment. 0.01mm is VERY sensitive.

We have our own test for 0.01mm precision ready but we requested dev team to film the testing process soon. We would rather not post a non-3rd party graph for objectivity purposes.

It is important to note that tests are always tests. And next goes, how can we take advantage of 0.01mm precision? What is the best setting for my keyboard that can achieve high precision in competivie gaming? We will post separately.

We hope this series of articles could help you better understand FUN60 and the technology behind.